امروز دوشنبه ۱۸ فروردین ۱۴۰۴

اگر به یک وب سایت یا فروشگاه رایگان با فضای نامحدود و امکانات فراوان نیاز دارید بی درنگ دکمه زیر را کلیک نمایید.

ایجاد وب سایت یادسته بندی سایت

محبوب ترین ها

پرفروش ترین ها

پر فروش ترین های فورکیا

فارسی ساز Watch Dogs Legion

فارسی ساز Watch Dogs Legion فارسی ساز Sleeping Dogs

فارسی ساز Sleeping Dogs فول ست کردی2025 ارگ اندروید

فول ست کردی2025 ارگ اندروید آموزش جامع افزایش امنیت و ضد هک کردن وای فای

آموزش جامع افزایش امنیت و ضد هک کردن وای فای دانلود فایلهای بسته آمادهچاپ و نصب تابلو اعلانات مسجدنما هفته چهارم فروردین ماه 1404

دانلود فایلهای بسته آمادهچاپ و نصب تابلو اعلانات مسجدنما هفته چهارم فروردین ماه 1404 دانلود کتاب صوتی فوق العاده نیک سرشت

دانلود کتاب صوتی فوق العاده نیک سرشت پاورپوینت درس 10 تاریخ دوازدهم انسانی انقلاب اسلامی

پاورپوینت درس 10 تاریخ دوازدهم انسانی انقلاب اسلامی سوالات نهاد مبحث اسلام، مردم و ولایت از دیدگاه امام خمینی همراه با پاسخ

سوالات نهاد مبحث اسلام، مردم و ولایت از دیدگاه امام خمینی همراه با پاسخ دانلود کتاب صوتی فوق العاده موهبت شگفت انگیز خشم

دانلود کتاب صوتی فوق العاده موهبت شگفت انگیز خشم پاورپوینت با موضوع معرفی طاعون

پاورپوینت با موضوع معرفی طاعون پاورپوینت درس 14 دین و زندگی یازدهم انسانی: مرجعیت و ولایت فقیه

پاورپوینت درس 14 دین و زندگی یازدهم انسانی: مرجعیت و ولایت فقیه جزوات جامع و عالی سناریوی تقلب

جزوات جامع و عالی سناریوی تقلب آزمون های تمرینی سطر به سطر میکروطبقه بندی شده (QB) اطفال 3 اسنشیال نلسون (1160 سوال شناسنامه دار با پاسخ تشریحی)

آزمون های تمرینی سطر به سطر میکروطبقه بندی شده (QB) اطفال 3 اسنشیال نلسون (1160 سوال شناسنامه دار با پاسخ تشریحی) بسته بزرگ سوالات کامپیوتر و فناوری اطلاعات

بسته بزرگ سوالات کامپیوتر و فناوری اطلاعات جزوه کامل و جامع الکترونیک2 _ دانشگاه شریف

جزوه کامل و جامع الکترونیک2 _ دانشگاه شریف آزمونهای جامع شبیه سازی کنکور تجربی

آزمونهای جامع شبیه سازی کنکور تجربی آزمونهای جامع شبیه سازی کنکور انسانی

آزمونهای جامع شبیه سازی کنکور انسانی دبیری زیست شناسی

دبیری زیست شناسی خلاصه کل دروس علوم پایه تفکیک شده

خلاصه کل دروس علوم پایه تفکیک شده جزوه کامل فارماکولوژی به تفکیک کورسها

جزوه کامل فارماکولوژی به تفکیک کورسها جزوه فوق العاده تجزیه و تحلیل سیگنالها و سیستم ها

جزوه فوق العاده تجزیه و تحلیل سیگنالها و سیستم ها بسته جزوات تخصصی دینامیک

بسته جزوات تخصصی دینامیک جزوه دست نویس درس ریاضی 2استاد آقاسی

جزوه دست نویس درس ریاضی 2استاد آقاسی کتاب ماتریس ها و تانسورها در فیزیک تالیف ا. و. جوشی ترجمه باهر و ثامری پور به صورت PDF و به زبان فارسی در 442 صفحه

کتاب ماتریس ها و تانسورها در فیزیک تالیف ا. و. جوشی ترجمه باهر و ثامری پور به صورت PDF و به زبان فارسی در 442 صفحهپر بازدید ترین های فورکیا

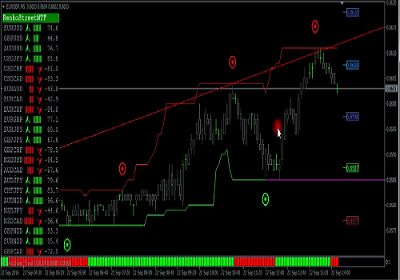

فروش فیلتر بورسی استریکلی فقط 75 هزار تومان

فروش فیلتر بورسی استریکلی فقط 75 هزار تومان کسب درآمد اینترنتی 300000 تومان در خانه در کمتر از 30 دقیقه

کسب درآمد اینترنتی 300000 تومان در خانه در کمتر از 30 دقیقه روش درآمدزایی در خواب (تعجب نکنید! کلیک کنید و بخوانید)

روش درآمدزایی در خواب (تعجب نکنید! کلیک کنید و بخوانید) کسب و کار اینترنتی با درآمد میلیونی

کسب و کار اینترنتی با درآمد میلیونی ربات همه کاره اینستاگرام

ربات همه کاره اینستاگرام كسب درآمد اينترنتي روزانه حداقل100هزار تومان تضميني

كسب درآمد اينترنتي روزانه حداقل100هزار تومان تضميني کسب درآمد ابدی و بی نهایت 100% واقعی

کسب درآمد ابدی و بی نهایت 100% واقعی کسب درآمد روزانه حداقل یک میلیون تومان ! کاملا حلال و واقعـی !!

کسب درآمد روزانه حداقل یک میلیون تومان ! کاملا حلال و واقعـی !! مجموعه ی آموزش تعمیر لامپ کم مصرف (از مبتدی تا پیشرفته)

مجموعه ی آموزش تعمیر لامپ کم مصرف (از مبتدی تا پیشرفته) افزایش ممبر کانال، گروه و ربات تلگرام به صورت بی نهایت (اد ممبر)

افزایش ممبر کانال، گروه و ربات تلگرام به صورت بی نهایت (اد ممبر) دانلود مجموعه آموزشی پایپینگ ( Piping ) و نقشه خوانی + آموزش سه نرم افزار طراحی و تحلیل لوله کشی صنعتی

دانلود مجموعه آموزشی پایپینگ ( Piping ) و نقشه خوانی + آموزش سه نرم افزار طراحی و تحلیل لوله کشی صنعتی آموزش بازكردن انواع قفل ها بدون كليد(ويژه)

آموزش بازكردن انواع قفل ها بدون كليد(ويژه) آموزش برنامه نویسی آردوینو

آموزش برنامه نویسی آردوینو کسب و کار اینترنتی در منزل

کسب و کار اینترنتی در منزل بازگردانی پیامک های حذف شده- ریکاوری پیامک ۱۰۰٪ عملی

بازگردانی پیامک های حذف شده- ریکاوری پیامک ۱۰۰٪ عملی آموزش رایگان کسب درآمد از سایت الیمپ ترید ( olymp trade )

آموزش رایگان کسب درآمد از سایت الیمپ ترید ( olymp trade ) اموزش ویرایش امضا و پکیج برنامه اندروید و کسب درامد از مارکت های اندرویدی

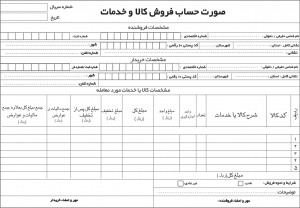

اموزش ویرایش امضا و پکیج برنامه اندروید و کسب درامد از مارکت های اندرویدی دانلود نمونه فاکتور آماده با فرمت ورد - اکسل و عکس

دانلود نمونه فاکتور آماده با فرمت ورد - اکسل و عکس آموزش ساخت بازی بدون دانش برنامه نویسی و طراحی سه بعدی مبتدی تا پیشرفته با نرم افزار

آموزش ساخت بازی بدون دانش برنامه نویسی و طراحی سه بعدی مبتدی تا پیشرفته با نرم افزار کد های آماده html و css جهت یادگیری و طراحی سریع

کد های آماده html و css جهت یادگیری و طراحی سریع آموزش كامل تعمير لامپ كم مصرف(اختصاصي)

آموزش كامل تعمير لامپ كم مصرف(اختصاصي) اموزش کسب درامد از اینترنت روزانه ۳میلیون تومان تضمینی و تست شده 1403

اموزش کسب درامد از اینترنت روزانه ۳میلیون تومان تضمینی و تست شده 1403 نسخه خطی اشعار و پیشگویی های شاه نعمت الله ولی

نسخه خطی اشعار و پیشگویی های شاه نعمت الله ولی نسخه خطی اشعار و پیشگویی های شاه نعمت الله ولی

نسخه خطی اشعار و پیشگویی های شاه نعمت الله ولی درامدزایی در خواب! (تعجب نکنید! بخوانید)

درامدزایی در خواب! (تعجب نکنید! بخوانید) مدار داخلی واکی تاکی(اموزش ساخت)

مدار داخلی واکی تاکی(اموزش ساخت) کتاب افزایش ممبر کانال تلگرام

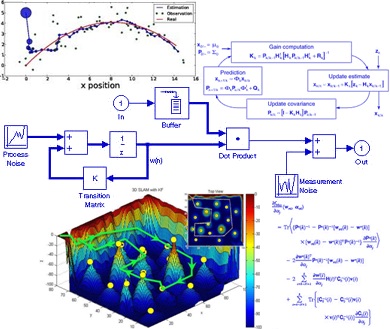

کتاب افزایش ممبر کانال تلگرام دانلود پاورپوینت فیلتر کالمن بر روی یک سنسور شتاب سنج برای تخمین سه متغیر حالت

دانلود پاورپوینت فیلتر کالمن بر روی یک سنسور شتاب سنج برای تخمین سه متغیر حالت اندیکاتور ای کیو آپشن

اندیکاتور ای کیو آپشنبرچسب های مهم

آمار بازدید سایت

پیوند ها

مقاله جوشکاری با عنوان : Parametric Studies and Finite Element Analysis of Welded Steel in Resistance Spot Welding Process

Kishore, N.1*, Sreenu, S.2, Ramachandran, N.3, Allesu, K.

چکیده :

Resistance Spot Welding (RSW) is a widely used joining process for fabricating sheet assemblies in the automotive,

marine and aerospace industries. Modern vehicles contain 2000-5000 spot welded points. The main requirements of

these automobile parts are corrosion resistance of chassis, the high strength values of sheets used, the stiffness of

welded joints when exposed to an external force and the ability to absorb impacts, along with low cost and comfort.

In RSW, electrodes travel on a predetermined path and make contact with the sheets at selected weld points to apply

force. Electric current is then turned on and flows through the sheets clamped between the electrodes. Due to the

contact resistance to current flow, the temperature rises from resistance heating. When the temperature reaches the

desired fusing temperature, a molten nugget is formed, the current is shut off after a designated time to allow the

nugget to cool down and solidification of the weld spot occurs under pressure. It is proposed to study the effect of

various parameters on nugget dimensions and strength of the weld joint in RSW and concentrating on different

material and thicknesses to get good weld joint at low cost and compared with analytical part done in Ansys.

مبلغ قابل پرداخت 2,000 تومان

برچسب های مهم